Plastics Rotomolding: Creating Customized Products with Versatility

The plastic-type material developing has evolved with time, and new techniques happen to be created to make your process convenient and effective. One of these brilliant approaches will be the rotational molding approach (rotomolding), that has been utilized for a long time. Rotomolding is a exclusive plastic-type material producing process that creates intricate plastic factors by spinning a hollow mold full of plastic-type resins. The ingredients created through this process works extremely well in a variety of business applications, from your auto Plastics Rotomolding market towards the medical market. In the following paragraphs, we are going to discover what rotomolding is, the way it operates, and its particular benefits.

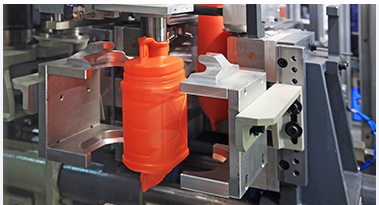

The rotomolding process begins with the reloading of the plastic-type resin in the fungus. The fungus will then be shut, along with the mildew is rotated in several instructions to permit the resin to fully fill up the mildew cavity. The mold is going to be warmed, along with the molten plastic material kinds a standard layer within the fungus. As the fungus is constantly spin, the plastic-type material cools down and solidifies, creating a hollow component that conforms exactly on the mold’s shape. The completed item is then taken from the fungus, and the procedure is prepared for the upcoming element.

The rotomolding method offers several positive aspects over other plastic production methods. First, it allows for complex forms and factors to become manufactured easily. The mildew may be developed with intricate details and intricate pieces, that may be tough and expensive to attain with some other methods. 2nd, the rotomolding method produces a standard wall size over the entire part. As a result the constituents stronger and more durable than once they have been produced making use of other approaches. Eventually, the rotomolding method needs a lot less supplementary completing job than other techniques. The parts are easy to remove from your fungus and applied specifically, decreasing misused some time and labour.

Rotomolding has a wide range of programs in various sectors. From the vehicle industry, rotomolded parts are used for gas tanks, dashboards, and engine addresses. From the medical care market, rotomolded parts are used for health care-class devices such as surgery containers and patient help solutions. From the telecommunications sector, rotomolded factors are used for property backyard gear, including signal amplifiers and transmitters.

In a nutshell:

Rotomolding is undoubtedly an innovative and successful plastic-type producing process that provides many advantages to people who apply it. It is a inexpensive method of generation that creates sophisticated parts with constant good quality and consistency. It offers an array of apps in various businesses, and it is becoming more and more fashionable as suppliers search for dependable and durable producing approaches. Should you be looking to get a far better way to produce powerful and trustworthy plastic factors, the rotomolding process could possibly be the respond to.