Rotational Molding: Creating Lightweight and Durable Plastic Components

Are you presently knowledgeable about the whole process of Rotational Molding, often referred to as Rotomolding? It’s a plastic-type material manufacturing approach that’s existed since the 1940s, but it’s in recent years that it is truly transformed the business. In this article, we will discover the science and art behind Plastics Rotomolding, examine the rewards it gives you manufacturers of plastic merchandise, and look at the position it plays in sustainability and enviromentally friendly duty.

What exactly is Rotomolding?

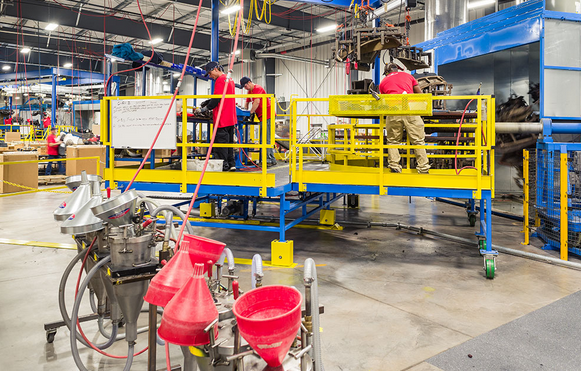

Rotational Molding, or Rotomolding as it is commonly abbreviated, is a plastic manufacturing method that involves melting plastic-type material natural powder inside a hollow mold, spinning the fungus consistently, and then allowing the plastic-type to cool and firm up. Rotomolding is a special procedure that generates products with robust, resilient, and standard wall surfaces of constant thickness. The rotational process warranties that most areas of the mold will get the same volume of molten plastic-type, which plays a part in its total consistency.

Great things about Rotomolding:

Probably the most considerable benefits of Rotomolding is being able to create big, sophisticated forms and pieces. As opposed to other plastic material developing strategies, Rotomolding has no size limits, making it perfect for producing big-level products, including tanks, storage containers, and play ground gear. Another advantage is the capability to manufacture hollow components without having to use seams or bones, reducing the likelihood of leaks or ruptures. Rotomolding is additionally highly adaptable in terms of the kinds of plastic resins that can be used along the way, which include polyethylene, polypropylene, and nylon material.

Sustainability and Environment Duty:

Rotomolding is a truly lasting manufacturing approach that features a minimum ecological affect. In contrast to injection molding, by way of example, Rotomolding uses a significantly decrease level of vitality and makes a lot less spend. In addition, a lot of the components applied in the process are recyclable, to enable them to be repurposed after the merchandise actually gets to the final of its lifecycle. Considering that Rotomolding generates extremely durable components, the products produced from the method are likely to not result in landfills in the near future. As a result, the process on its own, as well as the items produced by means of it, are important contributors to environmental and monetary sustainability.

short

Rotomolding can be a adaptable and innovative developing approach that offers huge good things about manufacturers, shoppers, and the surroundings as well. As consumer desire expands for environmentally-helpful and eco friendly products, it’s probably that we’ll see more and more companies adopting the Rotomolding technique. By investing in the science and art of Rotomolding, we are able to transform the plastic-type material market, producing goods that are solid, affordable, and eco-friendly.